Birk

Zukowsky

My name is Birk Zukowsky, and I am a fourth-year Product Design student at the Wilson School of Design at Kwantlen Polytechnic University. Born and raised in Richmond, BC, I have always liked viewing the world from different perspectives. In my second year, I completed a study abroad in Birk, Denmark to get an alternative outlook on not only design, but culture and history as well. I recently completed an internship and summer position as an Engineering Assistant at Makers Making Change creating assistive devices for people with disabilities using CAD modeling and 3D printing. With a love for 3D printing and helping those who are in need, I want to pursue my passion of making the world a better place.

Re-Print Vancouver

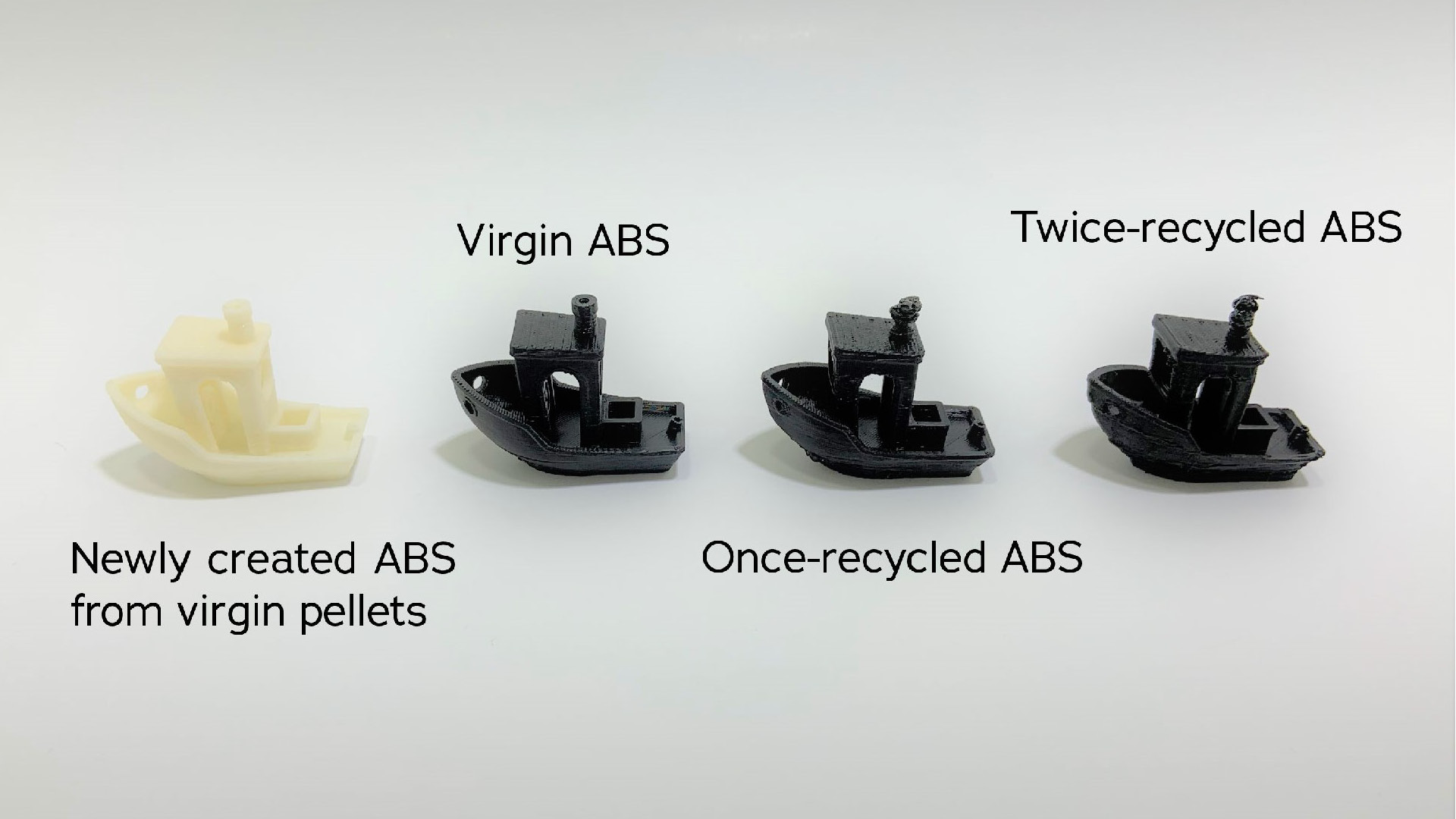

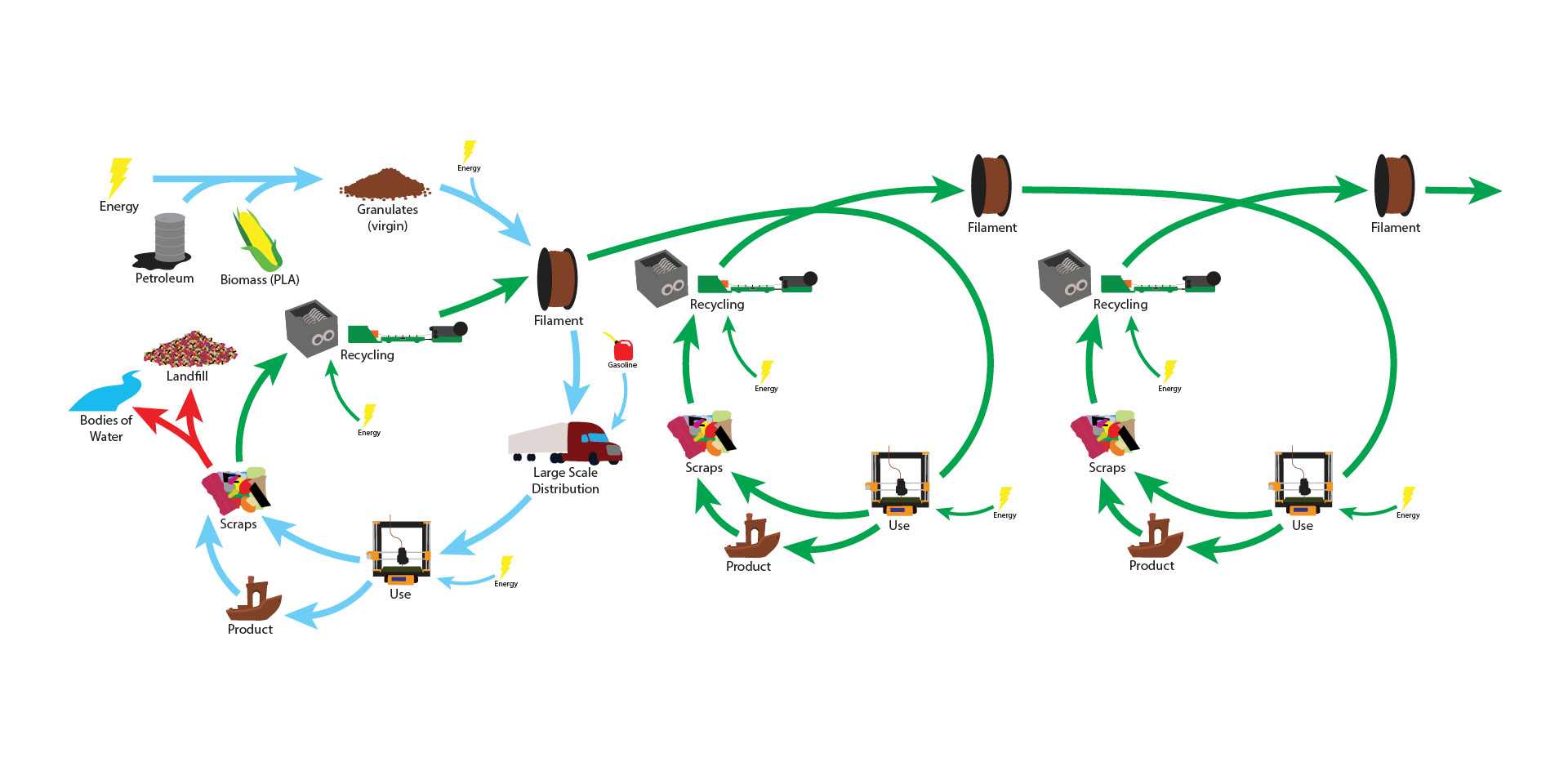

Re-Print Vancouver is a system based around the diversion of FDM 3D printing plastic waste from landfills by connecting 3D printing enthusiasts in the local printing community, collecting their scrap material, and turning it into reusable recycled 3D printing filament. This in turn creates a circular economy and closed loop system as the process can be repeated again and again. Through co-design, systems design, and physical prototyping, the system was designed and created, yielding usable once-recycled and twice-recycled filament. These samples of recycled filament are a proof of concept that the Re-Print Vancouver system operates successfully and has the potential to be expanded and scaled up in the future.

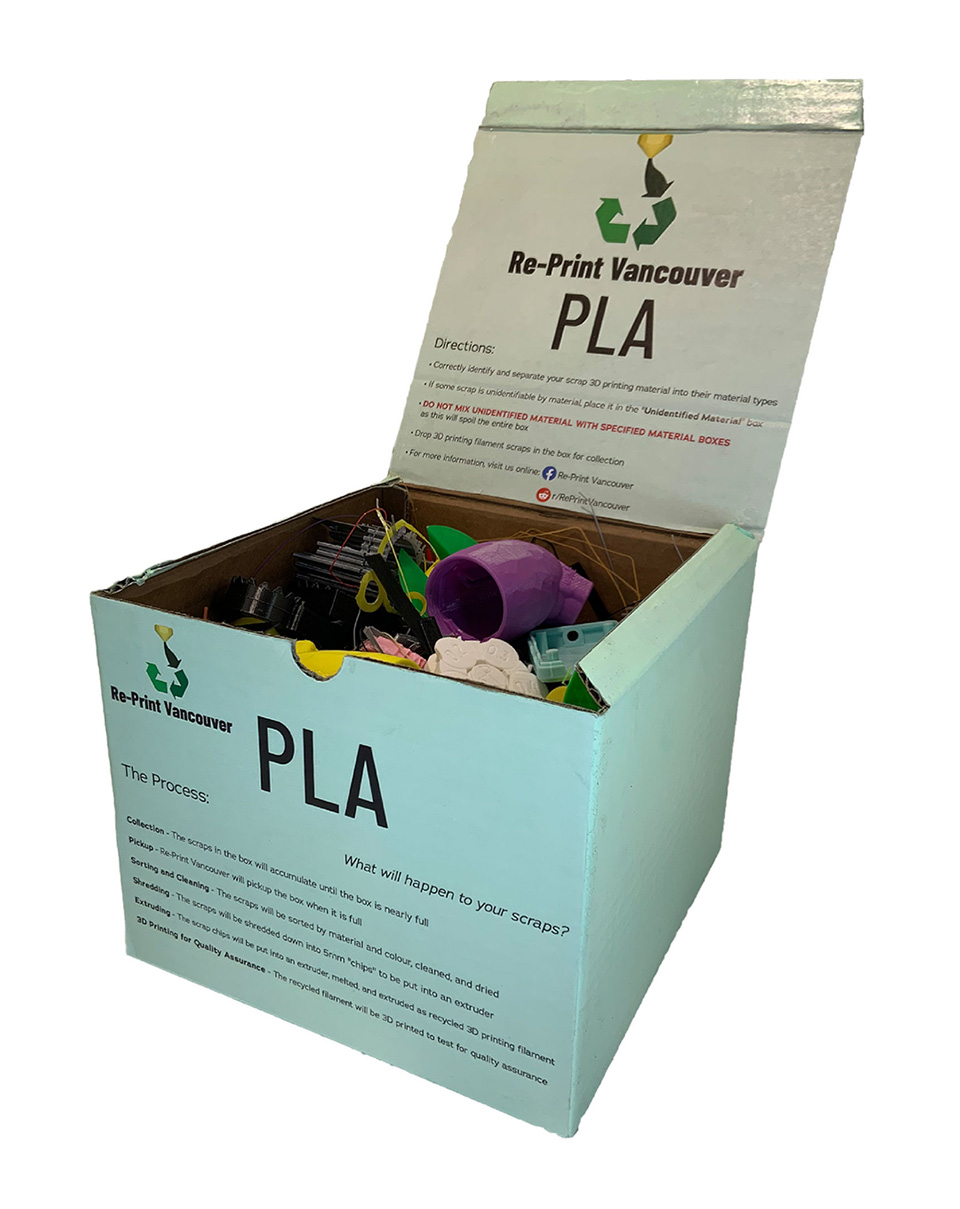

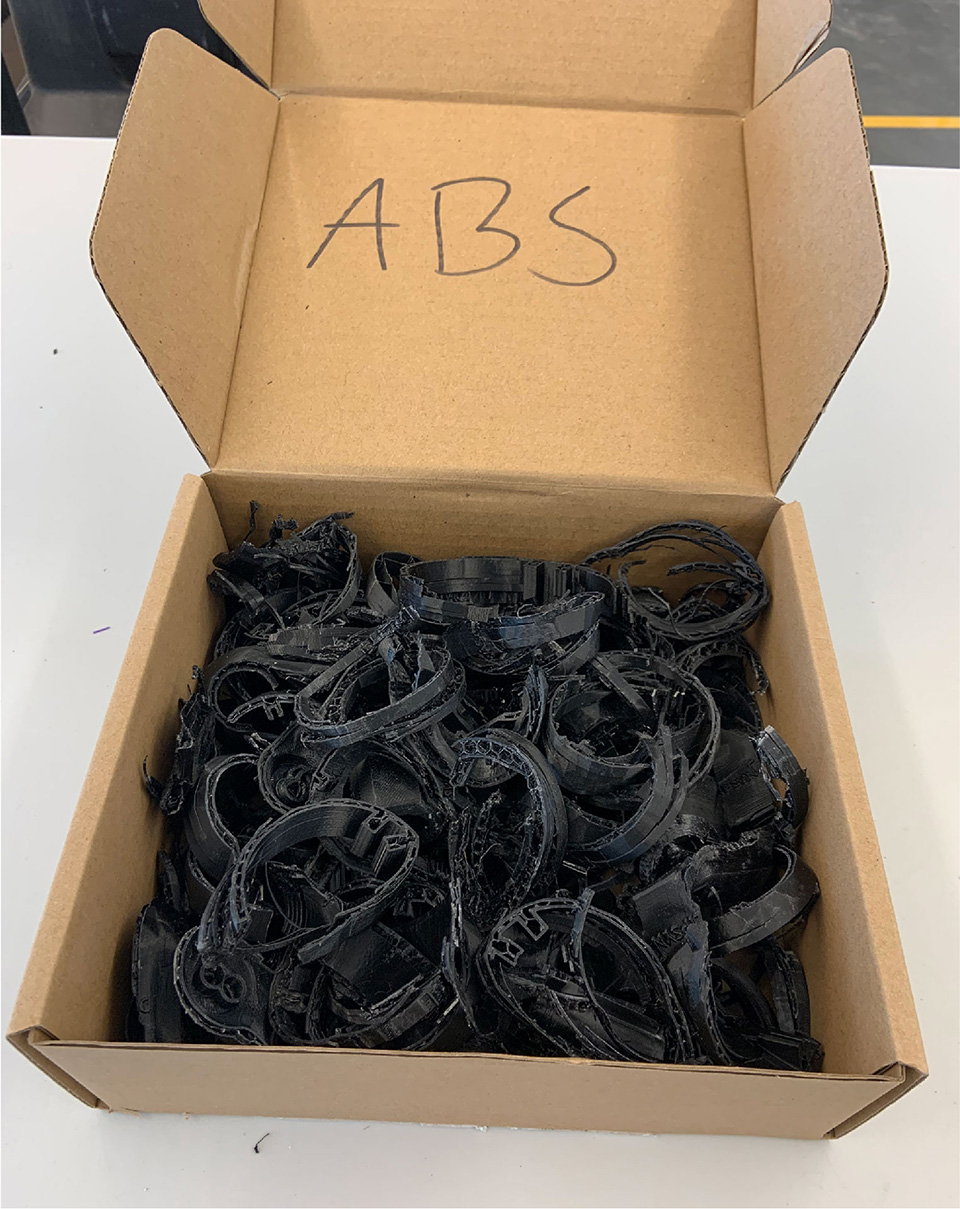

The system consists of an online social platform presence that enables the local 3D printing community to connect and promotes an environment for discussion and innovation while receiving centralized information and updates about the Re-Print system. Thereafter, the 3D printer enthusiast can begin collecting their scrap 3D printing material if they have not already done so and drop it off at a public Re-Print Vancouver donation collection station in an establishment near them. Once the donation boxes are full, Re-Print will collect the contents and prepare them for the recycling process. The scraps are then shredded into smaller pieces and put into a filament extruder and recycled filament is created. This recycled filament can be 3D printed with again, and the scraps from that can, again, begin their journey through the Re-Print Vancouver system, thereby creating a self-sufficient and sustainable system.