Naji

Kaddoura

A product designer who has an extreme attention to detail, strong visual communication skills and works well with others. His goal is to communicate his ideas visually through his illustration skills and passion to always learn and improve his ability which lead him towards to product design program. His dedication as a creative individual allows him to constantly improve through daily practice, and best represent his art and design in its truest form.

Self-taught artist since the age of fourteen. Usually spends his leisure time sketching, illustrating, and building prototypes. Drawing is his inspiration derives from watching animated series and therefore began to create anime self-portrait styles, logos, canvases, and storyboards.

Designer’s Perception of Environment

When I moved to Vancouver Canada at the age of 18, I was surprised about the discipline and respect of this beautiful city, where garbage is not to be found on the streets, each block consists of a bin separating between recycling, and garbage bins. At my house, every week they change into either collecting garbage or recycling which amazes me to this day of how these recycling companies are committing. Every two years, I start to move from a townhouse to a townhouse, and the only way to package all the stuff we ship is using cardboard boxing. To this day my garage is still filled with cardboards as it shows in the following image. From time to time, when I usually go to groceries, paperboard packaging has also been increasing my recycling. For these situations, I got curious and started to ask questions, where does cardboard and paperboard packaging go? Does it go to landfill or recycling? How might we reduce paperboard consumption throughout our daily spending?

Dry Food Hemp Packaging

Every year, the rate of deforestation has increased by over 10 million hectares, and 7.5 billion trees a year have been wasted on paper. The problem occurred where the increase of deforestation has impacted the use of pulpwood. From the statistics, looking into a different material that replaces pulpwood can be an ideal way of decreasing the potential of deforestation and providing an eco-friendly environment. Within the statistics, paper and cardboard packaging are the most consumed product of the pulpwood material.

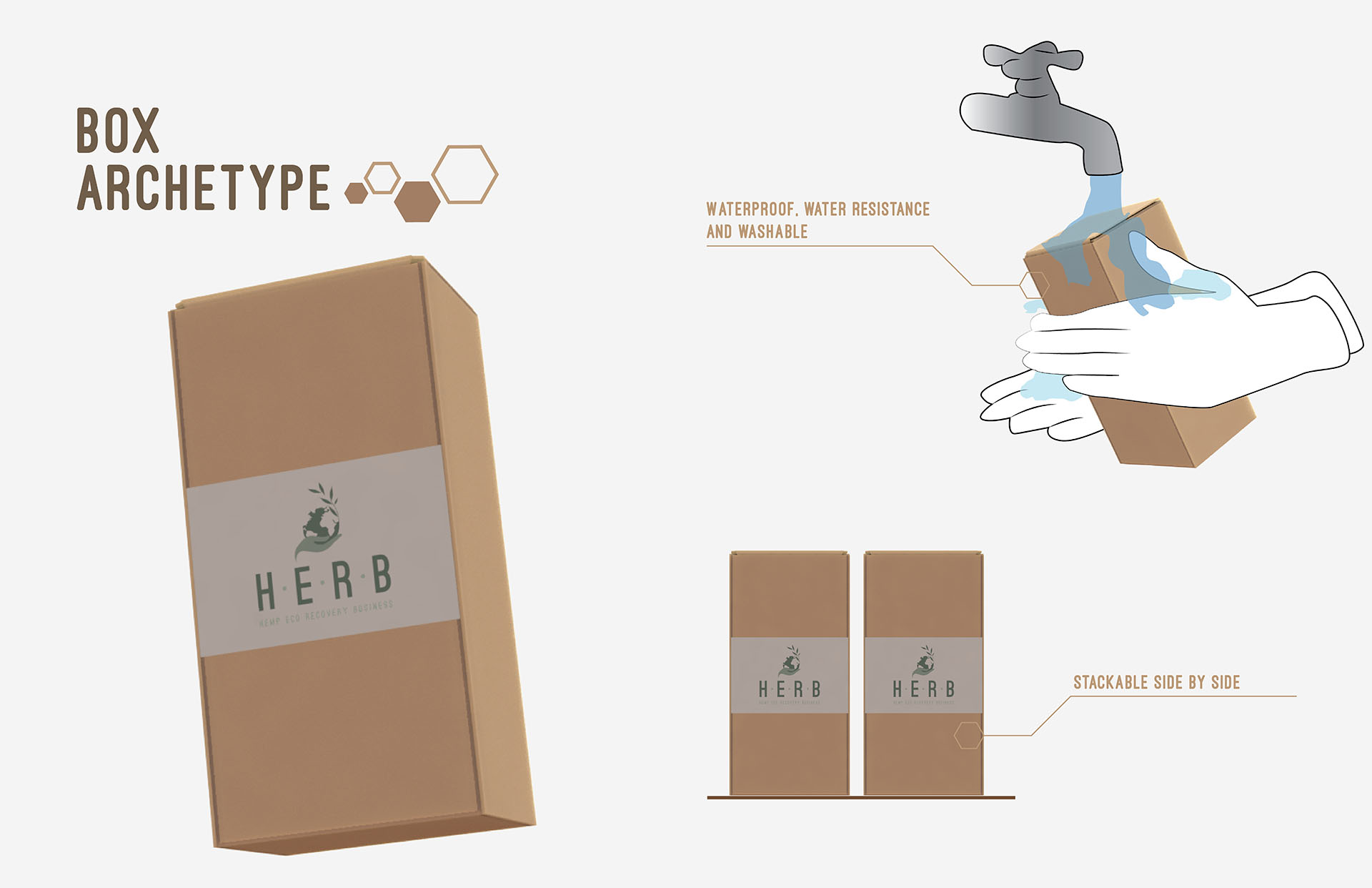

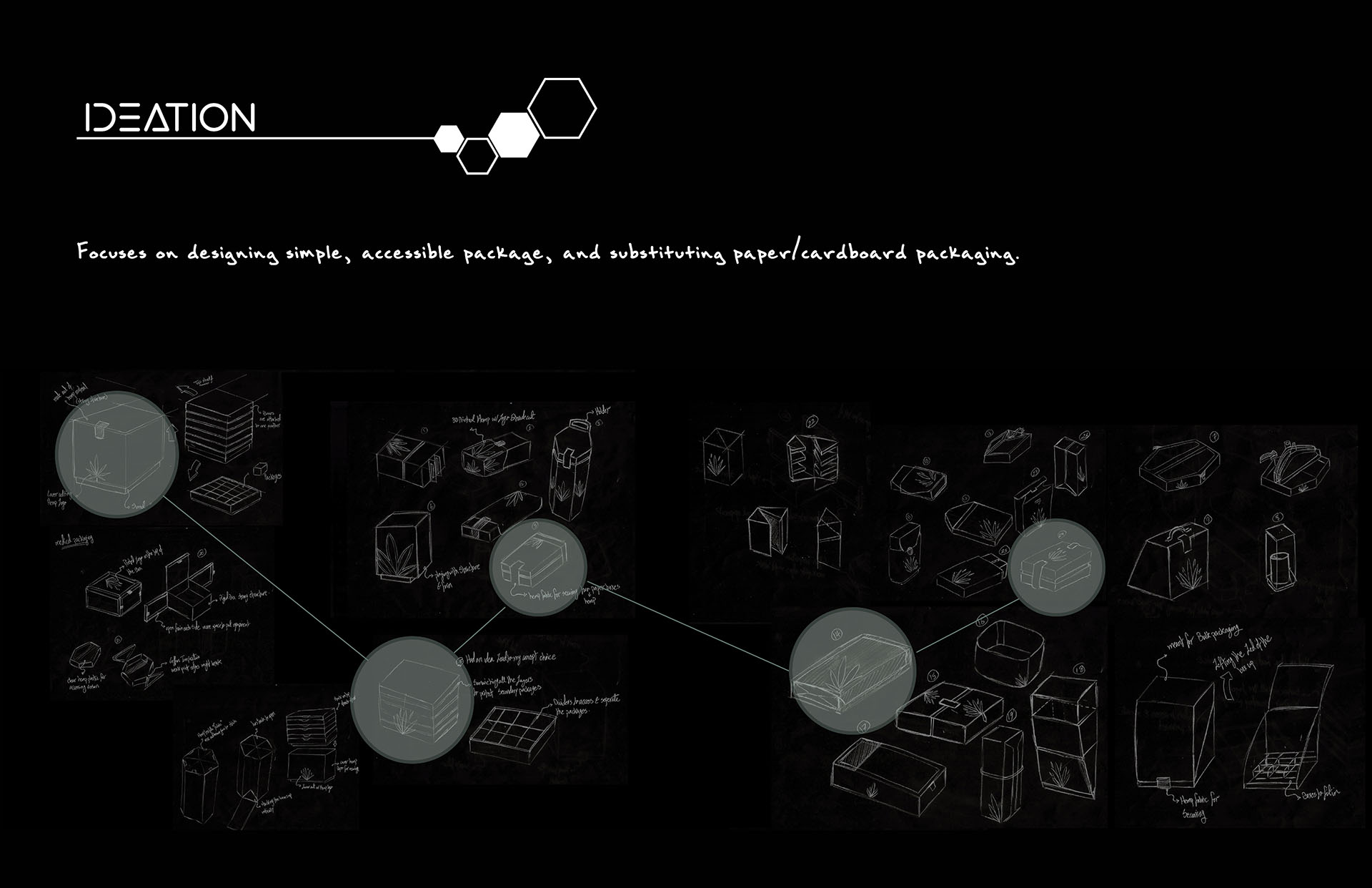

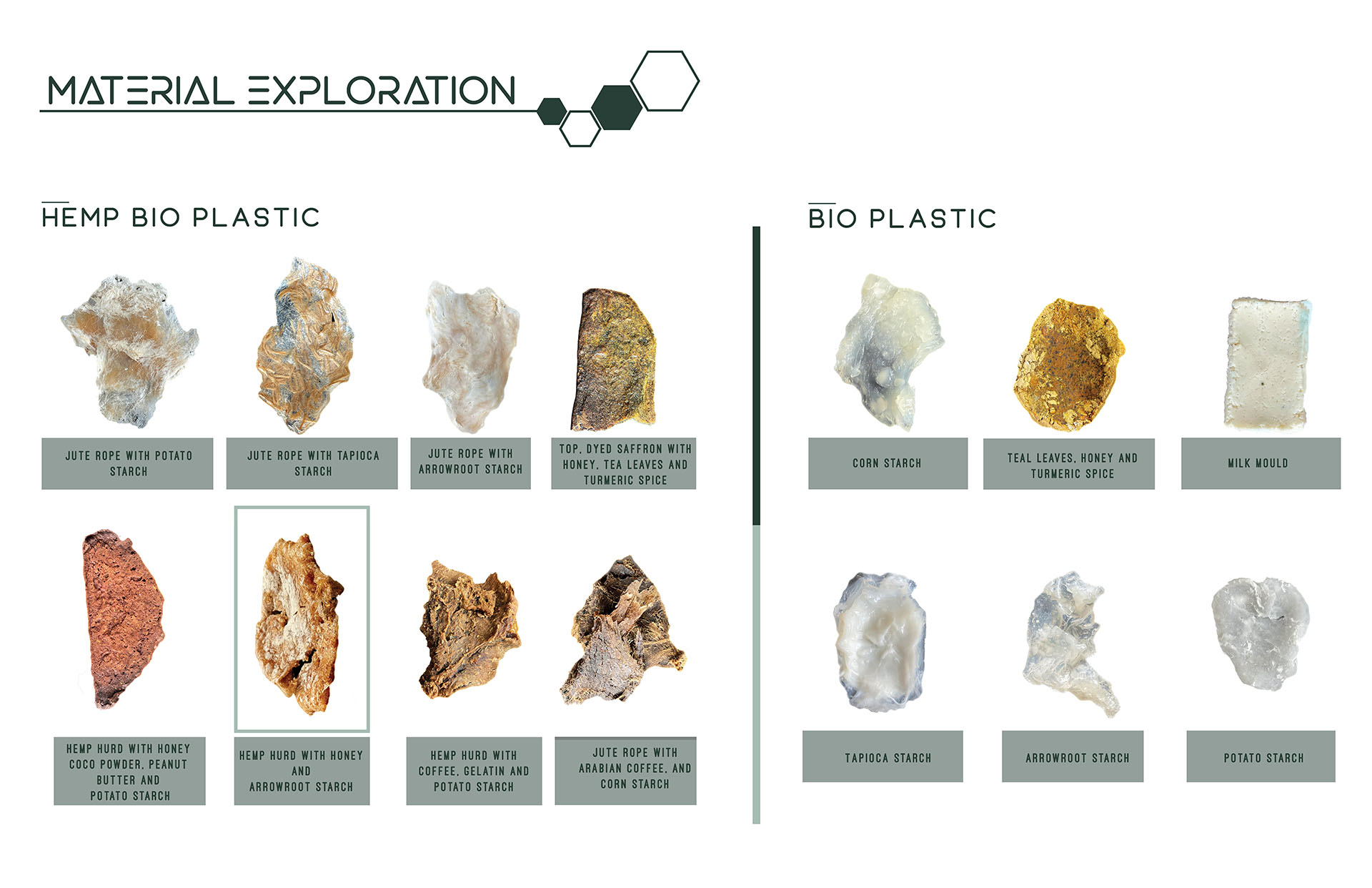

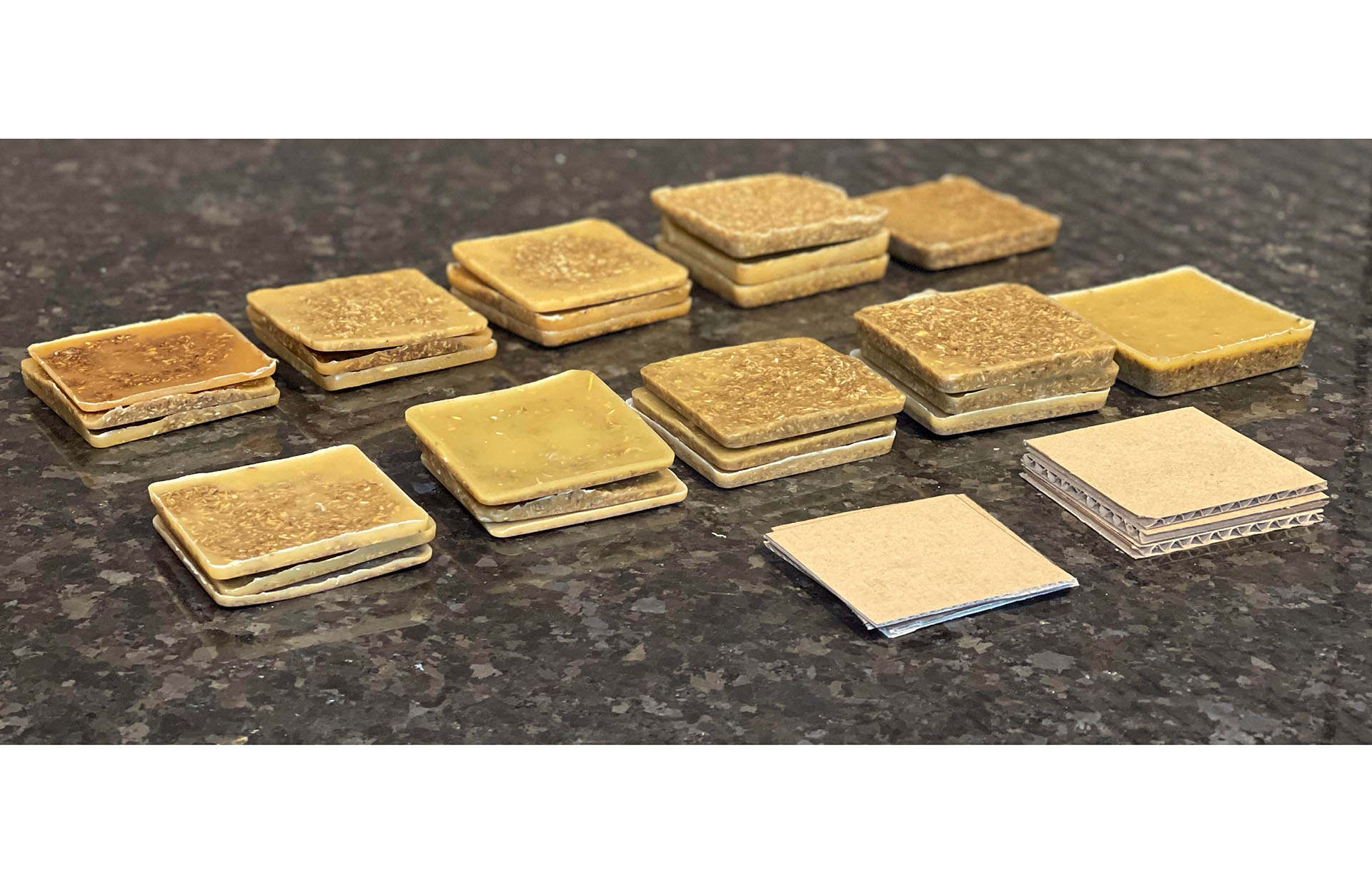

In order to study the problem, excessive research can be applied by pulpwood statistics, ethnographic research, Life cycle assessment of packaging, market, and social impact. The material that could hypothetically replace pulpwood is hemp material due to its sustainability, properties, and characteristics which surpass pulpwood. The area of focus to explore is dry food packaging where it is the most consumed product according to the expert in Canfor company. Creating prototypes of bio plastic and hemp bio plastic to compare their durability and found beeswax and hemp worked well together. Testing beeswax and hemp hurd material outline how to sample products, inspecting the sampling quality and generating multiple samples to therefore finalize the result. The first step of physical testing is sampling beeswax – hemp hurd material by pouring it into a silicon mold. Knowing the fact that four samples are generated per test with different thickness values: 2mm, 4mm, 6mm, and 8mm. These samples are set and prepared to therefore apply the standard tests of the dry food packaging requirements. The standard tests are important to help identify areas of the problem the packaging material may have. These standard tests are waterproof, water resistance, chemical resistance, air permeability, thickness, mass, and tensile strength. Second, applying these tests to cardboard and beeswax-hemp hurd and arrowroots with different thicknesses.